OUR PROCESS

Application

You leave an application by phone or online on our website

Examination

The master comes to you and conducts an examination

Cost of Repair

If the cost of the services announced by the mechanic

The repair is ready!

After the work is finished, you get a guarantee

Fast, Reliable, and Affordable Washing Machine Service in Chennai

Welcome to Repair City, your trusted partner for washing machine repair service in Chennai. We understand how essential your washing machine is to your daily routine. Whether you have a fully automatic, semi-automatic, top-load, or front-load washing machine, our certified technicians are equipped to diagnose and fix any issue quickly and efficiently.

With over 10 years of experience in appliance repair, we've served thousands of satisfied customers across Chennai. At Repair City, we pride ourselves on delivering transparent pricing, genuine spare parts, and a 6-month service warranty on all repairs. When your washing machine breaks down, we're here to get it back in perfect working condition-fast.

Call us today at 8148346609 for immediate assistance or book online for same-day service.

Why Choose Repair City for Washing Machine Service in Chennai?

We repair all types of washing machine problems for every major brand, including:

Washing Machine Not Spinning

If your clothes are coming out soaking wet, the problem is likely a faulty drive belt, worn-out motor coupling, or damaged lid switch. Our technicians can diagnose and fix spinning issues within one visit.

Washing Machine Not Draining

Standing water in your drum can damage your clothes and create mold. Common causes include a clogged drain pump, blocked drain hose, or faulty drain valve. We'll identify the root cause and restore proper drainage.

Washing Machine Making Noise

Grinding, squealing, or clicking sounds indicate wear and tear on internal components. Whether it's a worn drum bearing, broken pump impeller, or displaced object, our team handles all noise-related repairs.

Water Leakage

A leaking washing machine can cause water damage to your home. We repair cracks in the outer tub, fix faulty water inlet valves, and replace damaged hoses to prevent further damage.

Washing Machine Door Locking/Unlocking Issues

Front-load washers often have door lock problems. We repair faulty door latches and reset error codes to get your machine working again.

Poor Water Drainage

If water fills but drains too slowly, the drain pump filter or hose may be clogged. We clean filters and clear blockages to ensure proper water flow.

Our Washing Machine Services in Chennai

At Repair City, we provide comprehensive washing machine repair and maintenance services:

Fully Automatic Washing Machine Service - Expert repair for complex automatic systems

Front-Load Washing Machine Repair - Specialized service for high-efficiency models

Top-Load Washing Machine Service - Reliable repairs for traditional top-load machines

Washing Machine Spare Parts Replacement - Genuine replacement parts with warranty

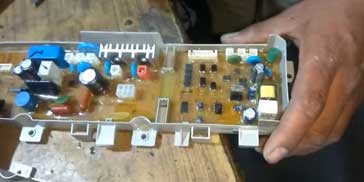

Washing Machine PCB & Circuit Board Repair - Electrical component expertise.

Drain Pump Replacement - Quick pump repairs to restore drainage

Drive Belt & Motor Coupling Repair - Fixing spin cycle issues

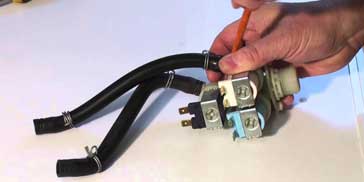

Water Inlet Valve Replacement - Ensuring proper water filling

Washing Machine Maintenance Service - Preventive care to extend appliance life

Why You Need Professional Washing Machine Repair

Attempting DIY washing machine repairs can be risky and often leads to more expensive damage. Here's why you should call Repair City:

Certified Technicians - All our technicians are trained and verified to handle complex appliance repairs safelys

Genuine Spare Parts - We use only original, market-available spare parts to ensure quality repairs

Transparent Pricing - Get a detailed estimate before we begin work. No hidden charges or surprise costs

Same-Day Service Available - We arrive at your location quickly and complete repairs on the spot whenever possible

30-Days Service Warranty - All repairs come with a 6-month guarantee. If the same issue occurs, we'll fix it free of charge

Pay After Service - Build trust with us. Pay only after your washing machine is repaired and tested

FAQ

1 What are the types of washing machines do you service?

We services all types of Fully-automatic washing machines

- Top-load

- Front-load

2 Do you provide warranty?

Yes, We provide 30 days warranty for all appliance repair and service.

3 What is inspection charge for washing machine?

If you are availing the service, no inspection charge only pay the service charge, Incase not availing the service you have to pay the inspection charge of Rs.199

4. Do you have customer support helpline?

Yes, you can reach our customer support 9 AM to 9 PM on all seven days 8148346609.

5. How long will it take to repair my appliance?

We recognize the essential role appliances play in your daily life, and our professionals will strive to repair them as swiftly as possible. The repair duration is influenced by factors like the nature of the issue and the availability of spare parts.

6. What if the same issue occurs again?

Our skilled professionals are committed to repairing your appliance with the utmost efficiency. However, if you experience the same issue recurring, we will gladly revisit and address the problem once again!

We Serve All of Chennai

Repair City provides washing machine repair service across all major areas of Chennai, including:

- Washing Machine Service in Velachery

- Washing Machine Service in Ambattur

- Washing Machine Service in Madipakkam

- Washing Machine Service in Tambaram

- Washing Machine Service in Porur

- Washing Machine Service in Perambur

- Washing Machine Service in Anna Nagar

- Washing Machine Service in Medavakkam

- Washing Machine Service in Kolathur

- Washing Machine Service in Poonamallee

- Washing Machine Service in Nanganallur

- Washing Machine Service in Chrompet

- Washing Machine Service in Kundrathur

- Washing Machine Service in Pallavaram

- Washing Machine Service in Perungudi

- Washing Machine Service in Mylapore

- Washing Machine Service in Mogappair

- Washing Machine Service in Pallikaranai

- Washing Machine Service in Sholinganallur

- Washing Machine Service in Adyar

- Washing Machine Service in Thiruvanmiyur

- Washing Machine Service in Thiruverkadu

- Washing Machine Service in Thoraipakkam

- Washing Machine Service in West Tambaram

- Washing Machine Service in T Nagar

- Washing Machine Service in Villivakkam

- Washing Machine Service in Kodambakkam

- Washing Machine Service in Adambakkam

- Washing Machine Service in Chitlapakkam

- Washing Machine Service in Alandur

- Washing Machine Service in Arumbakkam

- Washing Machine Service in Ayanavaram

- Washing Machine Service in Ayapakkam

- Washing Machine Service in Choolaimedu

- Washing Machine Service in East Tambaram

- Washing Machine Service in Guindy

- Washing Machine Service in Keelkattalai

- Washing Machine Service in Kilpauk

- Washing Machine Service in Kodungaiyur

- Washing Machine Service in Kovilambakkam

- Washing Machine Service in Madhavaram

- Washing Machine Service in Maduravoyal

- Washing Machine Service in Mangadu

- Washing Machine Service in Mogappair East

- Washing Machine Service in Mogappair West

- Washing Machine Service in Navalur

- Washing Machine Service in Nolambur

- Washing Machine Service in Nungambakkam

- Washing Machine Service in Omr

- Washing Machine Service in Pammal

- Washing Machine Service in Purasawalkam

- Washing Machine Service in Ramapuram

- Washing Machine Service in Redhills

- Washing Machine Service in Saidapet

- Washing Machine Service in Saligramam

- Washing Machine Service in Selaiyur

- Washing Machine Service in Thirumullaivoyal

- Washing Machine Service in Tiruvottiyur

- Washing Machine Service in Vadapalani

- Washing Machine Service in Virugambakkam

- Washing Machine Service in West Mambalam

Don't see your area listed? Call us at 8148346609 to check if we serve your location.

Customer Review

Over All Rating 4.9/5

Based on 33328 reviews and ratings

"Service exceeded my expectations. Bravo!"

Arjun

T. Nagar

"Quick, reliable, and friendly technicians."

Kavya

Chromepet

"Perfect service, my machine works like new!"

Madhavan

Virugambakkam

"Prompt service, excellent cleaning results."

Priya

Thirumazhisai

"Flawless work, highly recommend this service!"

Vijay

Egmore

"Efficient and professional every single time."

Lakshmi

East Tambaram

"Best washing machine service in town!"

Ramesh

Saligramam

"Fantastic service, saved me from hassle."

Shalini

Kundrathur

"Top-notch repair, machine runs perfectly."

Suresh

Chetpet

"Reliable service, fixed all issues promptly."

Divya

Sholinganallur

"Efficient, friendly, prompt service."

Ganesh

KK Nagar

"Great job, machine works like new!"

Meena

Pammal

"Quick, professional, and reliable."

Anand

Anna Nagar

"Top-notch service, highly recommend!"

Radha

Uthandi

"Excellent repair, very satisfied!"

Dinesh

Ramapuram

Our Work

Washing machine service in Chennai

washing machine bearings replacing

washing machine brushes replacing

washing machine service in Chennai

Error f08 replacing the heating element

Removing a foreign object from a machine

Repair of washing machine

Replacement of hatch rubber lock and board repair

Replacing washing machine brushes

washing machine drum change

Washing machine handle replacing at home

washing machine heating element replacing

washing machine lock replacing

washing machine hatch rubber and lock replacing

Washing machine tank rotted has crosspiece

How Our Service Works

We make washing machine repair simple and stress-free:

Call Us or Book Online - Reach us at 8148346609 or schedule service online for your convenience

Quick Diagnosis - Our technician arrives on time and thoroughly inspects your machine

Transparent Quote - We explain the problem and provide a detailed repair estimate

Approval & Repair - Repair begins only after you approve the cost

Parts Sourcing - We source genuine spare parts if needed (billed separately)

Complete Testing - We fully test your washing machine after repair to ensure it works perfectly

Need Washing Machine Repair in Chennai? We're Just a Call Away!